So, how long does it take to become a CNC programmer On average, it takes most individuals a combined total of four to five years of education from a university or training program, as well as firsthand experience gained on the job. Some companies will offer training for their employees, as well.So as we've discussed, the CNC machining process can be challenging to master but it is certainly not out of your reach. You should expect it to take over 3 years of hard work to master but it can take just a few hours of easy tutorials to create basic parts.The challenge of precision

CNC machinists work in a world where a micrometer, or a thousandth of an inch, can be the difference between perfection and waste. The high level of precision required, along with stringent quality control, constitutes one of the job's primary challenges.

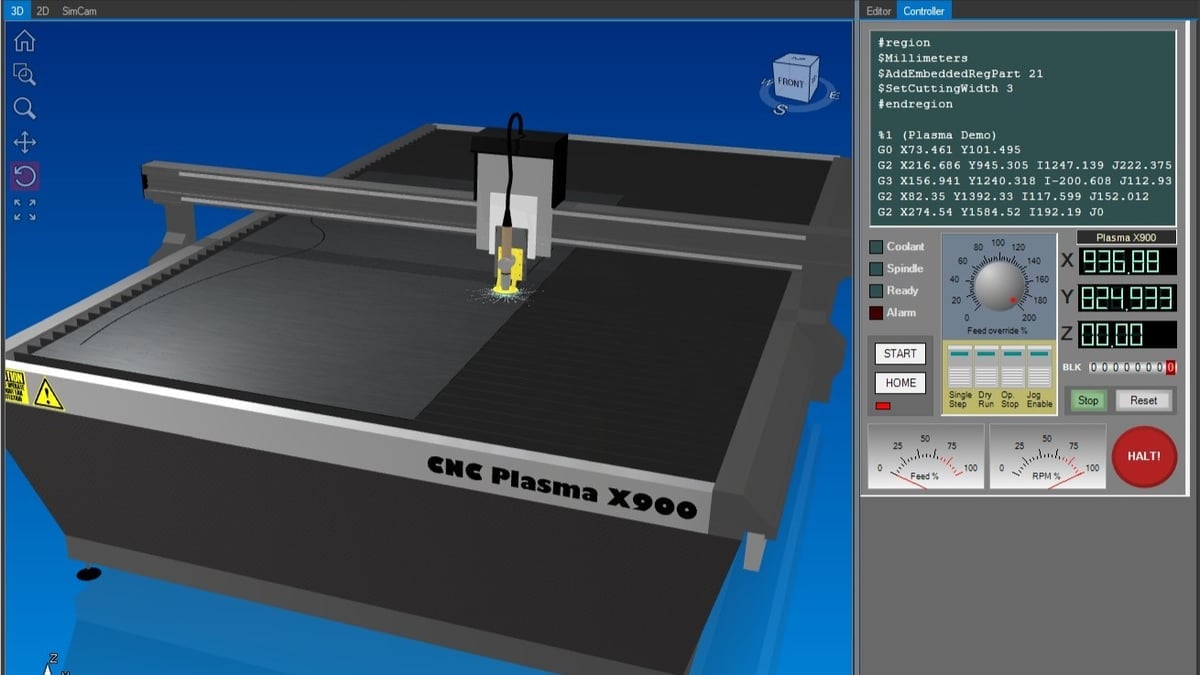

Does CNC require coding : CNC machines are automated manufacturing tools that perform precise and complex operations on various materials, such as cutting, milling, and drilling. CNC programming involves writing a series of commands, typically in the form of a programming language, G-code, that specifies the actions the CNC machine should take.

Is CNC machining stressful

CNC machining can be physically demanding, mentally challenging, and stressful at times. It demands precision, attention to detail, and a commitment to continuous learning. However, it also offers job satisfaction, opportunities for career growth, and competitive financial compensation.

Do CNC machines make money : One profitable way to make money with CNC machines is by manufacturing precision parts and components for various industries.

Spoiler alert, in Precision Machining, we all use a lot of math through algebra, geometry trig and statistics. Our machinists and quality technicians use and apply algebra, geometry, trig and statistics on the job everyday.

CNC work can be rewarding and challenging, but it also comes with its share of stress and fatigue.

Is CNC machinist a dying trade

Skills and experience required

The demand for skilled workers ensures that rapid CNC machining skills will continue to be needed in a variety of industries.CNC Programmer Salaries in India

The average salary for CNC Programmer is ₹50,000 per month in the India. The average additional cash compensation for a CNC Programmer in the India is ₹24,000, with a range from ₹3,600 – ₹1,85,808.There are several ways to program a CNC (Computer Numerical Control) machine using Python. One common approach is to use a library or module that provides a set of functions and classes for generating G-code, which is a standardized programming language for CNC machines.

An Easy Way to Make Money with a CNC: Machine Rental

If you have a CNC router that you only use for specific projects, or at specific times, consider renting out your device. You can rent the use of the device to trained machinists so they can do projects without having to buy or build their own CNC.

Is CNC a good career choice : CNC Machinists Work with High-Tech Equipment

CNC machinery is highly specialized equipment that requires training to use, but that's what makes this such a strong career choice. You may be one of only a few people in an entire manufacturing plant that knows how to operate the CNC equipment, which means job security.

Is CNC Operator a good career : It's a hands-on interface with the latest innovations, making every workday a step into the 'next big thing' in manufacturing. 2. Solid job prospects: Skilled CNC machinists are in demand now, and that demand will increase as the industry isn't attracting enough people to fill the roles available.

What language does CNC use

G-code, simply put, is the language that CNC machines understand. In this piece, we refer to all of this language as G-code, although it can be broken down into smaller pieces according to function: G, M, F, S, and T. Each letter differentiates different commands for the machining process: G: machine motion.

Going a bit further, the knowledge of common algebraic functions is definitely useful, mainly square roots and powers of a number. Second, since CNC programming is based on the relationship of points within a system of rectangular or polar coordinates, a good knowledge of basic geometry is also imperative.Life as a CNC programmer can be an exciting and rewarding path for those who love to create and have an eye for detail. This is a growing field filled with opportunities for those trained to work on complex CNC machines.

How hard is G-code : Contrary to what some people believe, G-code for CNC machine is not a difficult concept. It is very easy to understand the basics of G-code, how it works, and how to create a G-code for your next project.